FAQs

1. What is the working principle of incandescent and fluorescent?

In an incandescent lamp, a tungsten/ metal filament is heated by electric current until it becomes so hot that it glows to create light. Therefore incandescent bulbs release 90% of their energy as heat.

In a fluorescent lamp, an electric arc excites mercury atoms, which emit ultraviolet (UV) radiation. After striking the phosphor coating on the inside of glass tubes, the UV radiation is converted and emitted as visible light. A fluorescent lamp releases about 80% of its energy as heat.

2. How is the LED works?

An LED consists of a chip of semiconducting material treated to create a structure called a p-n (positive-negative) junction. When connected to a power source, current flows from the p-side or anode to the n-side, or cathode, but not in the reverse direction. Charge-carriers (electrons and electron holes) flow into the junction from electrodes. When an electron meets a hole, it falls into a lower energy level, and releases energy in the form of a photon (light). Photon is the light that is visibly seen by human.

3. Why do LEDs use such little power?

LEDs do not use a filament where a conductor is heated and light is created. Filament based lighting consumes more power than the light produced. Thus, LEDs are far more efficient in power consumption and light output.

4. Why does LED lighting cost more than traditional lighting?

LEDs can operate as standalone devices, but when grouped or clustered they require additional steps to operate properly. LEDs need proper components such as a circuit board, driving components and some cases and housings to endure the elements. LED circuits can be designed rapidly, but to ensure that they operate correctly and for long periods of time they require testing.

5. Do LEDs make heat

LEDs makes a little bit of heat. The heat noticed in some instances is due to on board components and other factors of the circuit. Compared to incandescent, LEDs make a fraction of heat. If LEDs are hot to touch, they are overpowered due to improper circuitry.

6. How LED emit different color?

The specific wavelength or color emitted by the LED depends on the materials used to make the diode. Red LEDs are based on aluminum gallium arsenide (AlGaAs). Blue LEDs are made from indium gallium nitride (InGaN) and green from aluminum gallium phosphide (AlGaP). White light is created by combining the light from red, green, and blue (RGB) LEDs or by coating a blue LED with yellow phosphor.

7. What is low power LEDs?

Low power LEDs commonly come in 5 mm size, although they are also available in 3 mm and 8 mm sizes. These are fractional wattage devices, typically 0.1 watt, operate at low current (~20 milliamps) and low voltage (3.2 volts DC), and produce a small amount of light, perhaps 2 to 4 lumens.

8. What is high power LEDs?

High power LEDs come in 1-3 watt packages. They are driven at much higher current, typically 350, 700, or 1000 mA, and—with current technology—can produce 40-80 lumens per 1-watt package.

9. Where have LEDs been used in the lighting industry?

LEDs are commonly used in aesthetic, effect, or specialty lighting applications, including architectural highlighting.

Most traffic lights and exit signs, for example, now use red, green or blue LEDs.

Early attempts to apply LEDs in general illumination lighting failed because they didn't meet the lumen-per-watt output or color requirements.

10. Why have past attempts to create general illumination LEDs failed?

Conventional approaches to develop general illumination LEDs often involved retrofitting existing fixtures to house the new LED technology. Thus, many early attempts simply used traditional lighting standards and housings.

Long-term research and development goal calls for white-light LEDs producing 160 lm/W in cost-effective, market-ready systems by 2025. Currently, the most efficacious white LEDs can perform similarly to fluorescent lamps.

11. Can LEDs function as efficiently in traditional fixture housing?

An LED module may physically fit into an existing housing, but that housing doesn't leverage the inherent qualities of the LEDs. Standard housings can't handle the challenges of LED thermal management, which is vastly different than thermal management for traditional incandescent or fluorescent lighting. Also, the optical design used in most traditional fixtures doesn't maximize the LED's efficiency.

12. What are the advantages to use LED lights?

LEDs bring several advantages to the lighting industry, including high efficiency and durability, and, with superior life over other lamp sources, their required maintenance is greatly reduced. This translates into energy savings, maintenance savings and an overall reduction in cost of ownership over the product's lifetime.

13. LED diodes need to be replaced?

An LED does not burn out like a standard lamp, so individual diodes do not need to be replaced. Instead, the diodes gradually produce lower output levels over a very long period of time. If one LED fails, it does not produce a complete fixture outage.

14. How should I dispose LED lamps?

LED lamps do not contain harmful metals or chemicals, thus it can be disposed like a normal incandescent light bulb.

15. Do LED lights burn out?

All lights have lumen depreciation, which means the light output slowly decreases over time. Unlike other types of lighting, LED bulbs do not burn out, but slowly decrease in brightness. Higher quality LED products have efficient heat sinks and LED chips. Heat sinks extract heat away from the LED junction and high quality LED Chips depreciate very slowly, while cheap chips can depreciate very rapidly. End life of LED products rate at 70% of initial luminous flux, or 70% of the original light output. All other lights from incandescent to metal halides burn out sooner and degrade much faster than LED lights. All other lights typically rate at when they burn out, LED lights rate and when they stop producing enough light. LEDs are more about lumen maintenance compared to end life. Improvements in packaging and heat sinking are improving the lumen maintenance characteristics of illumination-grade LEDs.

sewedborder

16. What is phosphor conversion?

Phosphor conversion is a method used to generate white light with LEDs. A blue or near-ultraviolet LED is coated with a yellow or multichromatic phosphor, resulting in white light.

17. What is luminous efficacy?

Luminous efficacy is typically used measure of the energy efficiency of a light source. It is stated in lumens per watt (lm/W), indicating the amount of light a light source produces for each watt of electricity consumed. For white high-brightness LEDs, luminous efficacy published by LED manufacturers typically refers to the LED chip only, and doesn't include driver losses.

18. What is CCT?

Correlated color temperature (CCT) is the measure used to describe the relative color appearance of a white light source. CCT indicates whether a light source appears more yellow/gold/orange or more blue, in terms of the range of available shades of "white." CCT is given in Kelvins (unit of absolute temperature).

19. What is CRI?

Color rendering index (CRI) indicates how well a light source renders colors of people and objects, compared to a reference source. Eight standard color samples are used in the test-color method for measuring and specifying the color rendering properties of light sources. CRI indicates how well a light source renders colors, on a scale of 0 to 100, compared to a reference light source of similar color temperature.

The test procedure established by the International Commission on Illumination (CIE) involves measuring the extent to which a series of eight standardized color samples differ in appearance when illuminated under a given light source, relative to the reference source. The average "shift" in those eight color samples is reported as Ra or CRI. In addition to the eight color samples used by convention, some lighting manufacturers report an "R9" score, which indicates how well the light source renders a saturated deep red color.

20. What is the difference between efficiency and efficacy?

Efficacy is a term normally used in cases where the input and output units differ. In lighting, we are concerned with the amount of light (in lumens) produced by a certain amount of electricity (in watts).

On the other hand, efficiency is a term that is typically dimensionless. For example, lighting fixture efficiency is the ratio of the total lumens exiting the fixture to the total lumens initially produced by the light source.

21. What is general illumination?

General illumination used to distinguish between lighting that illuminates tasks, spaces, or objects from lighting used in indicator or purely decorative applications. In most cases, general illumination is provided by white light sources, including incandescent, fluorescent, high-intensity discharge sources, and white LEDs. Lighting used for indication or decoration is often monochromatic, as in traffic lights, exit signs, vehicle brake lights, signage, and holiday lights.

22. What is energy efficiency?

Luminous efficacy indicates how much light the source provides per watt of electricity consumed. This is stated in lumens per watt (lm/W). Another measure of energy efficiency is the total watts a device consumes in providing the intended service. Both measures are important to consider. For example, an LED-based refrigerated display case light has lower lumens per watt compared to linear fluorescent systems, but uses about half the total watts to provide the necessary lighting.

sewedborder

23. What is lighting quality?

Lighting quality is a subjective term, but generally includes color quality (appearance, color rendering, and color consistency); illuminance levels (the amount of light the light source provides on a task or surface); photometric distribution of the light source in a fixture or luminaire; lifetime; ease of maintenance; and cost.

sewedborder

24. What is driver?

Fluorescent and high-intensity discharge (HID) light sources cannot function without ballast, which provides a starting voltage and limits electrical current to the lamp. LEDs also require supplementary electronics, usually called drivers.

The driver converts line power to the appropriate voltage (typically between 2 and 4 volts DC for high-brightness LEDs) and current (generally 200-1000 milliamps or mA), and may also include dimming and/or color correction controls.

25. What is driver loss?

Currently available LED drivers are typically about 85% efficient. So LED efficacy should be discounted by 15% to account for the driver.

sewedborder

26. How do you evaluate LED products?

Lumen output is only part of the story and can be misleading. To fully evaluate an LED product one needs to review the overall system efficiency, optical control, thermal management of the LEDs, and know at what point in time the fixture will reach 30 percent lumen depreciation. Products with good optical efficiency and thermal management will be able to deliver more lumens, on average, than traditional HID products.

As the Department of Energy concluded in its Solid-State Lighting Commercial Product Testing Program: "Until the field of SSL technologies and supporting knowledge matures, any claims regarding performance of SSL luminaires should be based on overall luminaire efficacy (i.e., from testing of the entire luminaire, including LEDs, drivers, heat sinks, optical lenses and housing), to avoid misleading buyers and causing long-term damage to the SSL market."

27. How LEDs able to outperform HID?

Super-bright white LEDs have the advantage of minimal lumen depreciation, better optical efficiency and high lumens per watt. This means these LEDs can be used to replace traditional HID luminaires. LEDs also have a vastly longer life span than traditional lamp sources. The fixture design also must be designed to leverage these inherent advantages of LEDs. LED fixtures also have an environmental advantage in that they contain no mercury, last longer and produce less waste, and they are made from fully recyclable materials. Furthermore, the extruded aluminium heat sink is manufactured using 77% post-industrial recycled material.

28. If an LED fixture has lower initial lumen output than a traditional HID light, how can LED claim to deliver lumens more efficiently than HID?

When you average delivered lumens over the course of 60,000 hours, you'll see that LED outperforms a 400-watt MH lamp operated in a horizontal position. (60,000 hours is used for this comparison to show three full life cycles of the HID.)

The MH's lumen depreciation, as well as optical and ballast losses, quickly reduce output of the HID system. Note that there are three relamps over 60,000 hours.

Conversely, LED has significantly better lumen maintenance and a more efficient driver. Also note that the LED fixture typically doesn't need relamping from zero to 60,000 hours.

Result: the LED's average delivered lumens is 74% higher than HID over 60,000 hours.

29.How to compare LED sources to traditional light sources?

Energy efficiency proponents are accustomed to comparing light sources on the basis of luminous efficacy. To compare LED sources to CFLs, for example, the most basic analysis should compare lamp-ballast efficacy to LED+driver efficacy in lumens per watt. Data sheets for white LEDs from the leading manufacturers will generally provide "typical" luminous flux in lumens, test current (mA), forward voltage (V), and junction temperature (Tj), usually 25 degrees Celsius. To calculate lm/W, divide lumens by current times voltage. As an example, assume a device with typical flux of 45 lumens, operated at 350 mA and voltage of 3.42 V.

The luminous efficacy of the LED source would be: 45 lumens / (0.35 amps x 3.42 volts) = 38 lm/W.

To include typical driver losses, multiply this figure by 85%, resulting in 32 lm/W. Because LED light output is sensitive to temperature, some manufacturers recommend de-rating luminous flux by 10% to account for thermal effects. In this example, accounting for this thermal factor would result in a system efficacy of approximately 29 lm/W. However, actual thermal performance depends on heat sink and fixture design, so this is only a very rough approximation. Accurate measurement can only be accomplished at the luminaire level.

30. What is application efficiency?

While there is no standard definition of application efficiency, we use the term here to denote an important design consideration: that the desired illuminance level and lighting quality for a given application should be achieved with the lowest practicable energy input. Light source directionality and intensity may result in higher application efficiency even though luminous efficacy is lower relative to other light sources.

sewedborder

31. How does ambient temperature affect LED efficiency?

LED fixtures must be designed with junction temperature thermal management as a key component and use the correct LEDs. These products will then be robust enough to operate in most ambient temperature applications. Unlike fluorescent sources, cold temperatures do not impact the performance of LEDs.

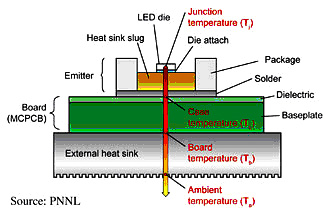

32. What is junction temperature?

Junction temperature is the temperature at the point where an individual diode connects to its base. Maintaining a low junction temperature increases output and slows LED lumen depreciation. Junction temperature is a key metric for evaluating an LED product's quality and ability to deliver long life.

The three things affecting junction temperature are:

- drive current

- thermal path

- ambient temperature

In general, the higher the drive current, the greater the heat generated at the die. Heat must be moved away from the die in order to maintain expected light output, life, and color. The amount of heat that can be removed depends upon the ambient temperature and the design of the thermal path from the die to the surroundings.

Heat management and an awareness of the operating environment are critical considerations to the design and application of LED luminaires for general illumination. Successful products will use superior heat sink designs to dissipate heat, and minimize junction temperature. The size of the heat sink is dependent upon the amount of heat to be dissipated and the material's thermal properties. Keeping the junction temperature as low as possible and within manufacturer specifications is necessary in order to maximize the performance potential of LEDs."

33. Why is the life span of an LED measured as lumen depreciation?

The life span of an LED is vastly longer than that of incandescent, fluorescent or HID lamp sources, generally lasting 50,000 hours or longer. Although the LED never really burns out, product life span is measured by lumen depreciation.

The Illuminating Engineering Society's (IES) current standard for calculating the life of an LED as the point at which the LED reaches 30 percent lumen depreciation.

Remember, a 100,000-hour rating is not equivalent to lamp life rating. LED life is rated where it has reached 30 percent lumen depreciation. At 100,000 hours an LED would still be operating, but at a decreased lumen output.

34. How long is 50,000 hours?

Based on how long a fixture is illuminated per day, here's what 50,000 hours works out to:

| Hours of operation in a day | Lifespan based on 50,000 hours |

|---|---|

| 24 hours | 5.7 years |

| 18 hours | 7.4 years |

| 12 hours | 11.4 years |

| 8 hours | 17.1 years |

| 4 hours | 34.2 years |

35. What is the Emergency Battery Back Up requirement ?

One essential requirement for public lightings in all buildings in Singapore is upon a power failure, a certain number of luminaries must remain lighted. This is to ensure that people affected by the power outage can easily find their way to safety, especially if the outage is coupled with a fire in the vicinity.

The power to light up these luminaries is derived from a built-in battery / inverter module, commonly called as EM pack.

Opto Global Tech does extensive testings to ensure that our LED lights work satisfactorily in tandem with their built-in EM packs so as to comply with requirements listed in SS563 : Part 2 : 2010. As to date, our T8, T5 and Ultra Thin Downlight models of LED lamps had been successfully tested to these requirements.

In order to meet the ever-changing and increasing demands of lighting industry, both locally and abroad, product improvements are rigorously pursued.